What are piezoelectric materials?

By Erling Ringgaard and Malte Aarenstrup Launbjerg

Piezoelectric materials can convert mechanical energy into electrical energy and vice versa. When exposing a piezoelectric material to mechanical stress, the material will polarize and generate an electric field so that a voltage can be measured between two opposite sides. Conversely, a piezoelectric material will either contract or expand when exposed to an external electric field. These phenomena are known as the direct piezoelectric effect and the converse piezoelectric effect, respectively.

What makes a material piezoelectric?

Piezoelectricity occurs in crystalline materials with no center point of symmetry in their unit cells (non-centrosymmetric crystals). As a result of this asymmetry, the centers of positive and negative charges within the individual unit cell will not coincide as its structure distorts at temperatures below the so-called Curie point. The separation of charges gives rise to a net dipole moment within the unit cell. An electric field will form between the dipoles and the piezoelectric material will polarize. The dipole moment and thereby the electrical energy generated can be increased by applying mechanical stress to the material parallel to the direction of the polarization.

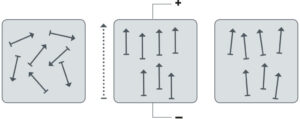

PZT crystal structure (perovskite type). Below the Curie temperature, the crystal changes from a centrosymmetric (left) to a non-centrosymmetric (right) shape, enabling piezoelectricity.

The piezoelectric effect is reversible as well, meaning that exposing a piezoelectric material to an external electric field will cause the material to either contract or expand depending on the direction of the field as the asymmetric charge distribution shifts in response. Applying an AC voltage to the piezoelectric material will force it to oscillate, effectively converting electrical energy into mechanical energy. This phenomenon is often used to produce sound waves and in particular ultrasonic waves.

Which materials are piezoelectric?

Multiple materials, both naturally occurring and synthetically manufactured, exhibit piezoelectric properties. They range from single crystals, over polycrystalline ceramics and polymer-based products to certain biological materials. Their one unifying factor is a non-centrosymmetric lattice structure similar to one of the 20 piezoelectric crystal classes.

Quartz was among the first materials discovered to have piezoelectric capabilities, and it remains one the most used single crystals in the piezoelectric industry. On several important parameters, it is, however, outclassed by polycrystalline ceramic materials among which lead zirconate titanate, popularly referred to as PZT, is the most common.

View our PZT materials here.

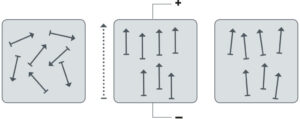

Contrary to single crystals, which have homogenous and continuous crystal lattices, polycrystalline materials, as the name implies, consist of many small crystallites – also known as grains – which are separated by grain boundaries. Each grain in a polycrystalline material is made up of dipole domains that are randomly oriented by default, meaning that little if any voltage would be generated by the material upon exposure to mechanical stress. The charges would simply shift in an uncoordinated manner with no net dipole moment. In order to attain its piezoelectric properties, a polycrystalline ceramic material must first be poled by a strong external electric field, meaning that it needs to be ferroelectric.

Ferroelectricity and reverse polarization

Polycrystalline piezoceramics belong to a material group known as ferroelectrics. The defining trait of this group is the ability to have their dipoles completely reversed. Applying a strong electric field to a ferroelectric material will force its dipoles to reorient themselves in accordance with the direction of the field until the point of polarization saturation is reached. If the electric field is reversed, so is the direction of the material’s dipoles. Even when the electric field is removed, the dipoles of the ferroelectric material will to some extent retain their orientation. This remanent polarization enables piezoelectricity in the material.

Dipoles in a piezoceramic material before, during and after poling.

Whereas piezoelectric single crystals must be cut in specific angles in accordance with the direction of their lattice structure to perform properly, ferroelectric materials such as PZT are much easier to customize in terms of shape and dimension thanks to their ability to have their polarization reversed.

ENGLISH

ENGLISH